Intervention tension frames

Design and build of first-of-kind systems to revolutionise safety and well access capability for three new-build offshore vessels.

Revolutionising well intervention operations.

Well intervention services leader Helix Energy Solutions approached us to discuss its operational requirements, challenges, and desires for three new-build vessels, Siem Helix 1, Siem Helix 2, and Q7000.

Helix sought to use our engineering capabilities to deliver a step-change in offshore personnel safety during well intervention, a range of operations carried out on an oil well during, or at the end of, its productive life. Well Intervention extends production by improving performance or providing access to additional or stranded oil reserves.

Working together, our shared goal was to achieve more streamlined, cost-effective operations than ever before. These ambitious objectives required working from first principles to redefine and increase what was possible operationally. We also developed new, much safer ways for personnel to access the well centre.

Delivering a step-change in operational safety.

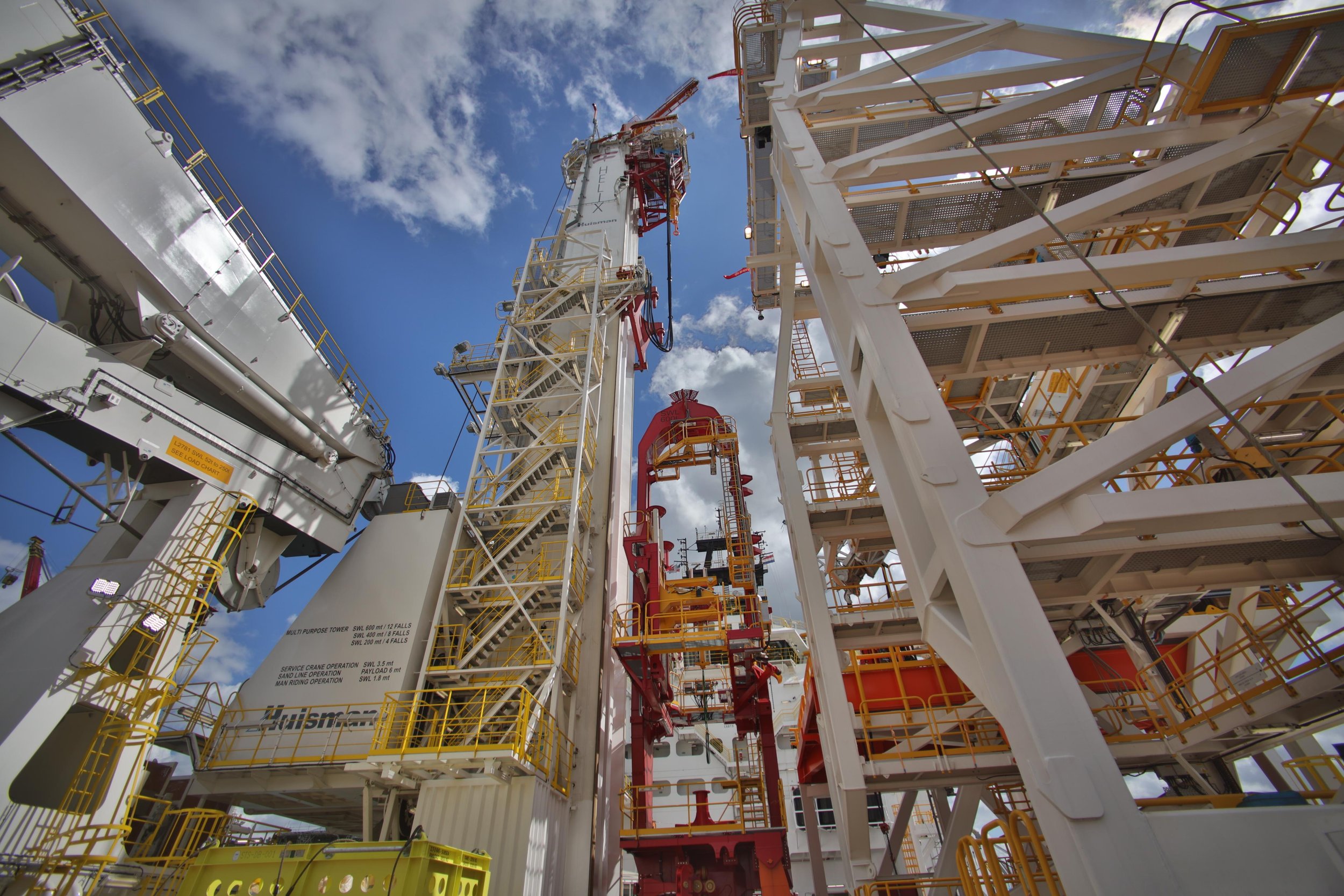

Following detailed discussions with Helix, we developed our Intervention Tension Frame (ITF) design, a bespoke 72 tonne, 20 metre tall system consisting of a primary load-bearing structure, with three working platform levels.

To meet Helix’s needs, the ITF design was shaped to be extremely innovative in terms of improving safety. The system offers unparalleled safe and integrated access to the riser, where simply none existed before. This removes the need for using man riding winches to achieve access, which significantly decreases the risk of injury to offshore personnel and means the system can be used in more challenging weather conditions.

The system also automates lifting activities using bespoke skidding systems; these were specifically designed to minimise risks to personnel associated with manual handling, during lifting operations.

The access offered by the ITF is split across three platform levels across the height of the system, providing personnel with unparalleled safe access where it’s needed. Additionally, the ITF incorporates a heave compensated drill floor, enabling personnel to move equipment from storage to operational positions more safely and easily. An Osbit-supplied walk to work gangway also supports safe access from the vessel deck, on to the ITF system itself.

Saving time while reducing project risk.

We increased movement and changeover capabilities by incorporating adjustable skidding systems to enable movement in three planes - an industry first.

This in turn, facilitates interchanging between coiled tubing and wireline operations, while remaining connected to the well riser, removing the need to return to shore between these operations, and for time-consuming tool changeover.

Streamlining this process enabled a 25-day time saving on the first Q7000 campaign and directly supported achieving an impressive 96.86% uptime rate, delivering significant cost-savings due to reduced vessel charter time.

A multi-award winning success.

Following a successful campaign for its first customer, Helix Energy Solutions won Petrobras’s ‘Supplier of the Year’ Award for its work conducted with the ITF on Siem Helix 2. Additionally, following this success, in 2022 Petrobras extended Helix’s initial contract for a further two years.

The ITF has won multiple prestigious industry awards and, after five years’ demonstration of commercial success, our ITF design was recognised with a Queen’s Award for Enterprise 2022 in the Innovation category.

-

In 2022, Osbit was presented with the Queen’s Award for Enterprise in the Innovation category, for the ITF design.

This prestigious award recognises outstanding achievement and commercial success as a result of innovation.

-

In 2017, Osbit was presented with the Subsea Innovation Award at the Annual Offshore Support Journal Conference, Awards and Exhibition, in London.

Voted for by the members of the offshore industry, the award recognises the achievements of owners of innovative subsea vessels, developers of subsea equipment, or contractors responsible for particularly innovative subsea projects.

-

In 2018, Osbit won the Health Safety and Environmental (HSE) Innovation Award at the 32nd SPE Aberdeen Offshore Achievement Awards (OAA) for the ITFs.

The HSE Innovation Award recognises outstanding HSE technology, process of system developed for the offshore gas or renewables industry, notably those that have either reduced the environmental impact of the sector or improved individual, plant or operational safety.

Osbit Director Steve Bedford speaking with King Charles II ahead of our Queen’s Award presentation.

Osbit Engineer Martin Jolliffe collecting our Offshore Achievement Award for the ITFs in Aberdeen.

“Osbit is a supplier that is able to listen to our requirements and translate them into practical, high quality and cost-effective results, time and time again.”