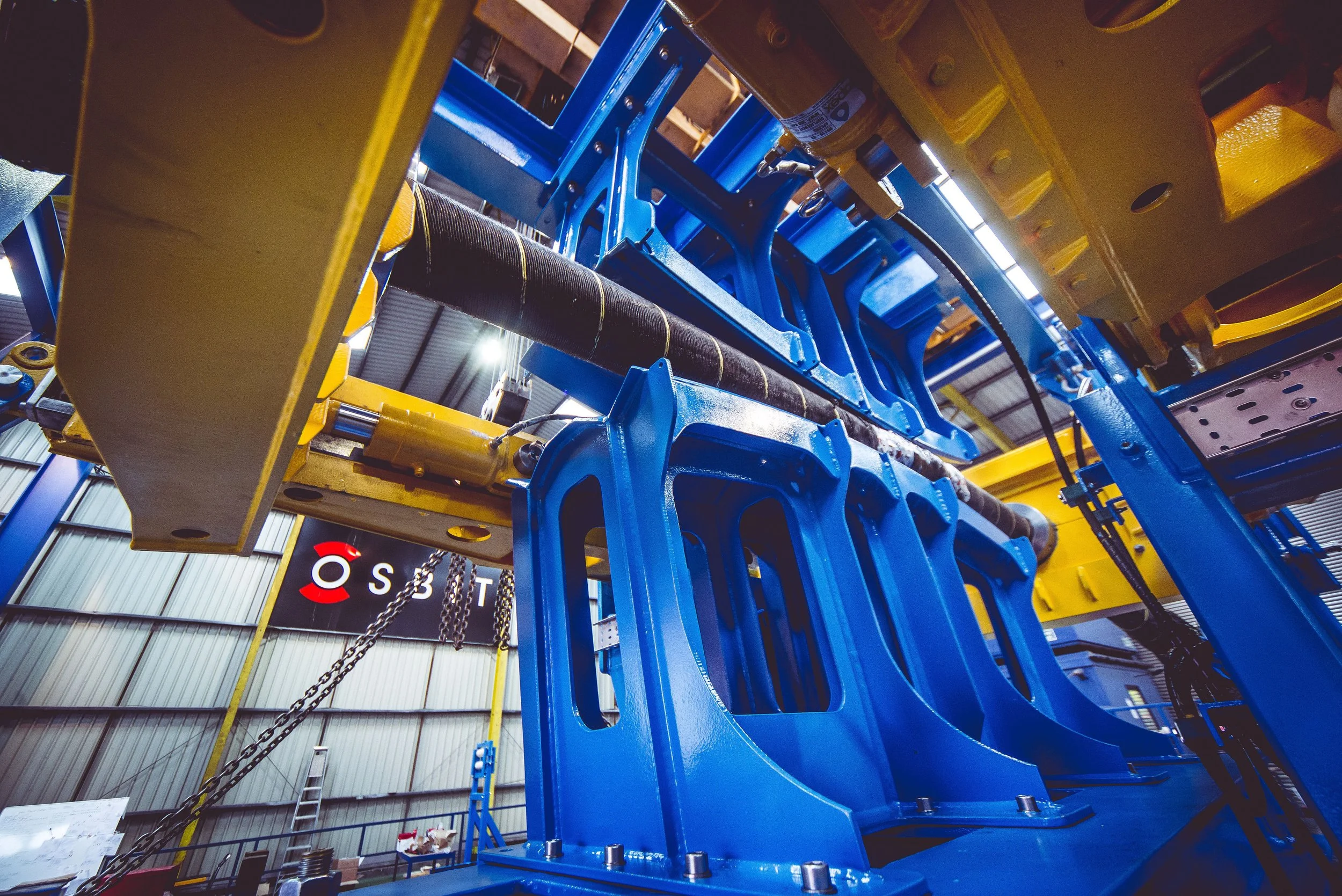

Dynamic subsea cable test rig

Design and build of a uniquely capable system to support the development of floating wind farms across the globe.

Supporting the next generation of renewable subsea cables.

ORE Catapult, the UK's leading Technology Innovation and Research Centre for Offshore Renewable Energy, approached Osbit to support the development of a state-of-the-art cable bend fatigue rig, for testing subsea cables.

The test rig’s purpose was to support the development, and improve the performance and reliability, of subsea cables. More specifically, the system needed to be capable of testing floating wind and tidal cables, support carrying out operational research and act as a representative test bed for all aspects of subsea cable development.

Innovative engineering to improve cable reliability.

With cable-related failures accounting for up to 80% of offshore wind project insurance claims, the rig we designed and built enables the innovative testing of offshore array and subsea cables to improve their efficiency and resilience. This in turn directly supports the development of next generation wind farms and the associated electrical infrastructure.

In particular, the development of floating wind represents an important economic opportunity for UK companies in research and development, design and manufacturing – with 4GW of installed floating wind capacity expected by 2030, representing an annual market value of £3bn.

To improve on existing standards and realise these future opportunities, we incorporated market-leading capabilities into our system:

-

The test rig offers market-leading testing capabilities, achieved through innovative design.

These include the ability to test up to three samples simultaneously, and performing electrical and mechanical testing simultaneously.

-

We designed the test rig to be able to offer a huge range of testing options.

As well as being used in ORE Catapult’s UKAS-accredited laboratory, the system can be used while fully submerged in seawater, and the cable can be energised while putting mechanical forces on to it.

-

This fully bespoke system is robust in design and construction to meet the rigorous demands of system’s full operational life-cycle.

Reducing offshore project risk.

The development and qualification of dynamic cables and connectors suitable for floating wind is crucial for the successful development of the sector, especially as this type of wind farm is located further from shore and therefore is subjected to harsher conditions.

The offshore renewables sector has identified cables as a key area for technological improvement, and vigorous testing requirements are a key part of this.

In developing this test rig system in partnership with ORE Catapult, Osbit was able to provide a versatile and robust system to aid this vital industry progression.

“This rig enables us to add another dimension to our service, bringing mechanical testing to subsea components which is required as part of the conformance and validation testing for dynamic operation in offshore wind farms.

In doing this, we are able to improve the efficiency, performance and resilience of subsea cable systems.”